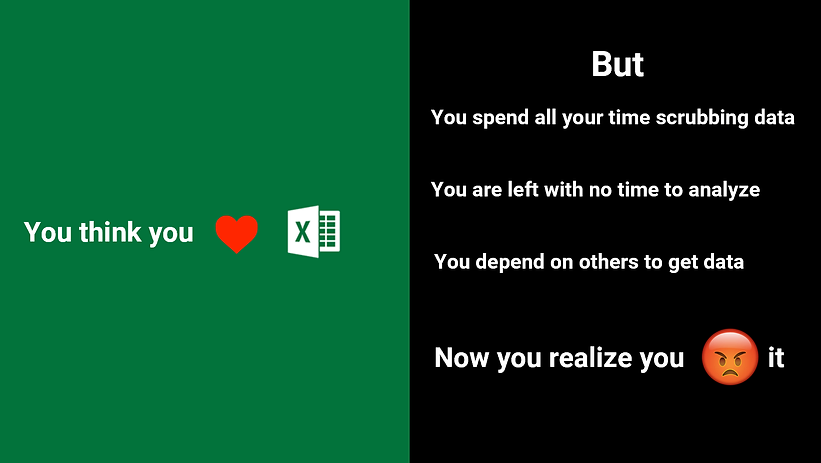

Do you feel like you spend all your time inputting data into an enormous spreadsheet?

Do your spreadsheets have so many links, look-ups, and connections that adding a new product, material, vendor, or any other piece of data takes weeks (and multiple attempts) to complete?

Do you have a team of analysts who spend more time inputting data than actually analyzing it?

Do you present top-level data at meetings and hope that no one requests more detail because: a) you won’t be able to immediately answer the question and, b) finding the answer requires hours, days, or weeks and is about as easy as finding a needle in a haystack?

You, my friend, are not alone. Having worked in Supply Chain for decades, I can honestly say that it does not matter whether the company is large or small, global or local, technologically advanced or not, turning the sheer volume and complexity of data generated through a Supply Chain into actionable information is a challenge.

Take for example a mid-size manufacturer of consumer and industrial electronics with whom we recently worked. This company sources materials primarily from suppliers in Asia and produces approximately 600 finished goods. Because of the nature of their product portfolio, long lead-times and multiple distribution centers, both in North America and internationally, are necessary. They run on a tier-one ERP system (implemented about 15 years ago) however the data within this ERP is not easily accessible. Inundated by Excel spreadsheets, their Supply Chain analysts spend many days each month creating reports that provide a view to high-level inventory numbers (units and dollars). They know they are heavy on inventory but not why. They lack visibility to granular data and are unclear about which metrics would be most beneficial in their analysis.

This electronics company looked to The Owl Solutions for assistance. In a matter of days, the team from The Owl Solutions was able to install their supply chain performance platform, extract the necessary data from the company’s existing ERP, and provide them with a dashboard of standard supply chain performance metrics reports.

Immediately, the time spent unproductively crunching data, managing Excel spreadsheets, and creating high-level reports was reduced by 90%. The analysts now had both the granular detail and the time to effectively analyze performance and, in less than 6 months, inventory performance improved by 15%.

Leveraging the easy-to-use Owl dashboards, the Supply Chain team can develop data-driven insights, more easily interpret results and explain performance to management, anticipate questions and be prepared to respond in meetings, proactively identify potential problems and course correct, and quickly provide the data and analysis needed to facilitate quicker decision-making. For example, the Supply Chain team used the Inventory Dashboard to analyze and discuss positive working capital and cash flow management with their Finance colleagues. This dialogue has opened the doors to greater collaboration between the two teams, driving decisions based on facts and figures not gut feelings.

Operational efficiency, employee efficiency and effectiveness, cost reductions, and collaborative and productive partner discussions are just some of the benefits that can be achieved by combining data with business intelligence.

Owl can help you mine real-time data in your existing ERP or transactional system and turn it into clear, understandable business metrics that can drive better, more informed business decisions.